What are the commonly used truck parts?

2024,12,17

The following are some commonly utilized truck parts:

I. Engine-Related Components

Air Filter

- Function: The air filter serves to filter the air entering the engine. By preventing dust, impurities, and the like from entering the cylinders, it ensures the cleanliness of the engine's intake air, thereby prolonging the engine's service life. In the event that the air filter becomes clogged, it will result in insufficient intake air for the engine, leading to a decrease in power and an increase in fuel consumption.

- Types: There are two main types, namely dry and wet. The dry air filter features a simple structure and filters the air through filtering materials such as filter paper. On the other hand, the wet air filter utilizes oil to absorb dust.

Oil Filter

- Function: The oil filter filters out metal filings, carbides, dust, and impurities in the engine oil. This ensures the cleanliness of the engine oil and reduces the wear of engine components. The oil filter needs to be replaced regularly. Otherwise, if it becomes clogged, it will affect the normal circulation of the engine oil.

- Common Brands: Brands such as MANN and Bosch are commonly known. The filters of these brands are of reliable quality and possess good filtering effects.

Fuel Filter

- Function: The fuel filter filters out impurities in the fuel, such as rust and dust. This prevents these impurities from entering components such as fuel injectors and fuel pumps, thus avoiding fuel system failures. For diesel trucks, due to the varying qualities and impurity contents of diesel, the role of the fuel filter is particularly crucial.

- Replacement Cycle: Generally, it needs to be replaced after driving a certain mileage depending on the fuel quality and usage conditions. For example, it is typically replaced after about 10,000 - 20,000 kilometers.

Spark Plug (for Gasoline Trucks)

- Function: The spark plug generates an electric spark in the combustion chamber of the engine to ignite the mixture, enabling the engine to operate normally. The performance of the spark plug directly impacts the ignition effect and combustion efficiency of the engine.

- Types: There are several types including ordinary spark plugs, platinum spark plugs, and iridium spark plugs. Iridium spark plugs have a long service life and excellent ignition performance, but they are relatively expensive.

Fuel Injector (for Diesel Trucks)

- Function: The fuel injector sprays the fuel into the cylinders of the engine in the form of a mist. This allows the fuel and air to be fully mixed, ensuring that the fuel can burn efficiently and completely. The injection precision and spray pattern of the fuel injector have a significant impact on the power output and fuel economy of the engine.

- Maintenance: Since the impurities in diesel are prone to clog the fuel injector, it needs to be cleaned and maintained regularly.

II. Brake System Components

- Function: Brake pads are key components of the brake system. When the brake pedal is pressed, the brake pads come into contact with the brake discs (drums) to generate friction, causing the wheels to stop rotating. The quality of the brake pads is directly related to the braking performance and driving safety of the truck.

- Materials: Generally, there are semi-metallic, ceramic, and other materials. Ceramic brake pads offer good braking performance, low noise, and little wear, but they are relatively expensive.

- Replacement Cycle: They may need to be replaced after driving about 30,000 - 50,000 kilometers depending on the usage conditions.

- Function: Brake drums (used for drum brakes) and brake discs (used for disc brakes) are the main components that bear the braking friction. Brake discs have good heat dissipation performance and a stable braking effect and are increasingly widely used in modern trucks. Brake drums have a simple structure and low cost.

- Inspection Points: It is necessary to check the wear degree, flatness, and other aspects of the brake discs (drums). If the brake discs are excessively worn, it will lead to problems such as shaking during braking and an increase in the braking distance.

Brake Master Cylinder and Slave Cylinders

- Function: The brake master cylinder converts the force of the driver pressing the brake pedal into a hydraulic signal and transmits it to the brake slave cylinders through the brake pipelines. The brake slave cylinders then push the brake pads to contact the brake discs (drums) to achieve braking.

- Maintenance: It is necessary to ensure the sealing of the brake master cylinder and slave cylinders to prevent brake fluid leakage. In case of leakage, it will lead to brake failure, which is a very dangerous situation.

III. Chassis Components

Tires

- Function: Tires are the only parts of trucks that make contact with the ground. They bear the weight of the vehicle, provide traction and braking force, and also play a role in cushioning the impact of the road surface. The quality and condition of tires have a significant impact on the driving performance, safety, and economy of trucks.

- Types: There are radial tires, bias tires, and others. Radial tires have good wear resistance and low rolling resistance and are currently the commonly used tire types for trucks.

- Maintenance: It is necessary to regularly check the tire pressure, tread depth, and wear condition. Insufficient tire pressure will increase fuel consumption and aggravate wear. Excessive tire pressure will affect the comfort and handling of the vehicle.

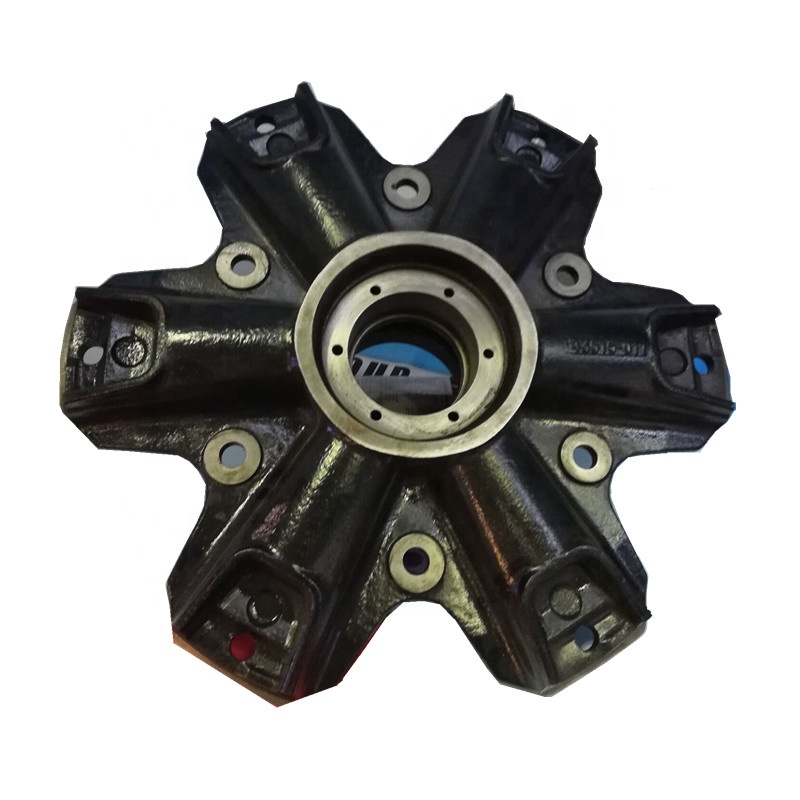

- Function: Wheel hubs are the parts for installing tires and also bear the weight of the vehicle and various forces during the driving process. The strength and quality of wheel hubs are of great importance. Poor-quality wheel hubs may be deformed or broken.

- Materials: There are steel wheel hubs, aluminum alloy wheel hubs, and others. Aluminum alloy wheel hubs are lightweight and have good heat dissipation performance, but they are relatively expensive.

Suspension System Parts (such as Shock Absorbers, Leaf Springs) - Function of Shock Absorbers: Shock absorbers absorb and buffer the vibrations caused by the uneven road surface, making the vehicle run more smoothly, improving riding comfort, and also protecting other parts of the vehicle from being damaged by excessive vibrations.

- Function of Leaf Springs: Leaf springs mainly play a load-bearing role and also have a certain shock absorption function. The elasticity and strength of leaf springs should meet the load-bearing requirements of the vehicle. Otherwise, they are prone to breakage.