Among the numerous components of a semi-trailer, the

Leaf Spring undoubtedly holds a pivotal position. It is not only directly related to the vehicle's load-bearing capacity and driving stability but also closely connected to driving safety. Therefore, knowing how to select high-quality and suitable leaf springs for semi-trailers has become a crucial skill that every vehicle owner must master.

I. Confirm the Suitable Model Semi-trailers of different models vary greatly in their design specifications and technical parameters, and naturally, the suitable leaf springs also differ. Take the common box semi-trailers and dump semi-trailers as examples. Box semi-trailers are mostly used for cargo transportation on smooth roads, and they have relatively high requirements for the comfort and conventional load-bearing performance of the leaf springs. On the other hand, dump semi-trailers often operate in complex and harsh construction site environments and frequently deal with heavy loads. This requires the leaf springs to have stronger load-bearing capacity and fatigue resistance. Usually, they are larger and thicker in specification, and the number of leaves will also increase accordingly. When making a purchase, vehicle owners must carefully consult the vehicle operation manual of the semi-trailer, which contains detailed records of the vehicle's various technical parameters and the models of suitable components. If the operation manual is unfortunately lost, you can directly contact the vehicle manufacturer to obtain accurate and error-free adaptation information. Do not make a purchase randomly based solely on experience or subjective assumptions. Otherwise, once the model does not match, it will not only be difficult to install but may also pose serious safety hazards during use.

II. Distinguish Product Quality

(I) Inspect the Geometric Dimensions During the manufacturing, transportation, and storage processes of leaf springs, if the operation is improper or they encounter accidental collisions, they are likely to be deformed. Once the geometric dimensions change, the performance of the leaf springs will be greatly reduced, and they will not be able to function properly. When making a purchase, you can use professional measuring tools to accurately measure the key dimensions of the leaf springs, such as length, width, and thickness, and carefully compare them with the nominal dimensions of the product. If the error between the two exceeds the reasonable range, even a slight deviation may have an adverse impact on the driving stability and safety of the vehicle. Such products should never be purchased.

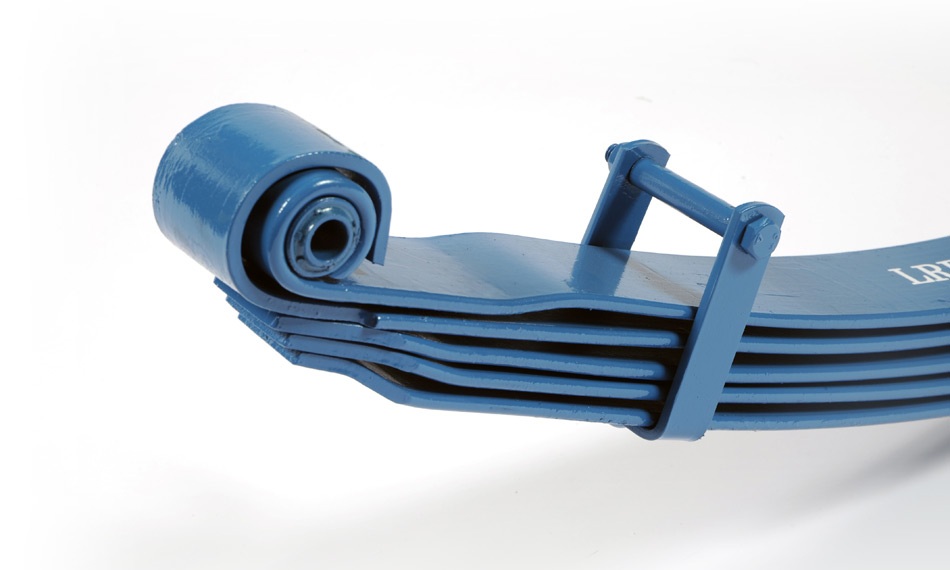

(II) Examine the Joint Parts During handling and storage, due to external forces such as vibration and collision, the joint parts of the leaf springs are extremely prone to defects such as burrs, indentations, damage, or even cracks. These hidden flaws in the joint parts will seriously affect the overall structural strength and service life of the leaf springs. During the vehicle's driving process, once subjected to greater pressure, it is very likely to cause the leaf springs to break, leading to serious traffic accidents. Therefore, when making a purchase, be sure to carefully check the joint parts of the leaf springs to ensure that their surfaces are smooth and flat without any obvious flaws. If problems are found in the joint parts, you should not hesitate to give up this product and look for other reliable leaf springs.

(III) Observe the Surface Condition For qualified leaf springs, their surfaces not only have a certain precision to ensure good coordination with other vehicle components but also should present a shiny finish, which indicates the strict control of the surface treatment process by the manufacturer during production. When making a purchase, carefully observe the surface of the leaf springs to check for any rust spots, signs of mildew, or problems such as cracking and loss of elasticity of rubber parts. In addition, if obvious tool marks appear on the surface, it is likely that there are process defects in the product during processing, and such products should also not be selected.

III. Consider the Load-bearing Capacity

During the actual operation of a semi-trailer, the weight of the goods carried and the driving road conditions vary greatly. This requires the leaf springs to have sufficient and suitable load-bearing capacity. Generally speaking, regular leaf spring products will clearly indicate their rated load-bearing capacity when leaving the factory. When making a choice, vehicle owners need to comprehensively consider factors such as the types and weights of goods that the semi-trailer often transports and the actual driving road conditions. If the semi-trailer is mainly engaged in the transportation of heavy goods, such as building materials and ores, or often drives on roads with poor conditions and large bumps, then leaf springs with stronger load-bearing capacity must be selected. And in order to deal with possible short-term overloading situations (although overloading is not advisable, there will inevitably be special circumstances in actual transportation), a certain safety margin should also be appropriately reserved. It is recommended to select leaf springs whose rated load-bearing capacity is 20% - 30% higher than the actual maximum load to ensure that the vehicle can drive safely and stably under various working conditions.

IV. Pay Attention to the Material Characteristics Currently, the materials used for manufacturing leaf springs for semi-trailers in the market are mainly alloy spring steels. Among them, silicon-manganese steel has been the most widely used in China due to its good comprehensive performance. Different materials have different characteristics, which have a decisive impact on the performance of the leaf springs. For example, carbon spring steel has relatively low hardenability and is used less in the automotive field. Although manganese steel has good hardenability, it is prone to cracking during the quenching process and has problems such as temper brittleness. Silicon-manganese steel, on the other hand, not only has high strength and elastic limit but also has an ideal hardenability. It can effectively improve the fatigue resistance of the leaf springs and extend their service life while ensuring that the leaf springs have sufficient load-bearing capacity. Therefore, when selecting leaf springs, it is necessary to fully understand the characteristics of different materials and choose the most suitable material according to the actual usage scenarios and working conditions of the semi-trailer.

V. Take Note of the Processing Technology The processing technology of leaf springs is complex and precise, covering multiple key processes such as blanking, straightening, drilling, ear rolling, quenching, medium-temperature tempering, shot peening, assembly, and pre-compression. The technological level and quality control of each process are directly related to the final performance and quality of the leaf springs. For example, in the quenching and medium-temperature tempering processes, precisely controlling the heating temperature, holding time, and cooling rate can enable the leaf springs to obtain an ideal organizational structure and mechanical properties, significantly enhancing their strength, toughness, and fatigue resistance. Shot peening treatment can not only form a strengthening layer on the surface of the springs to improve the surface hardness but also effectively remove tiny defects and decarburization phenomena on the spring surface, reducing stress concentration and thus greatly increasing the service life of the leaf springs. However, if the processing technology is rough and the quality control of each process is not in place, it is very easy to cause internal defects in the leaf springs, such as cracks and uneven hardness, seriously affecting their quality and safety. Therefore, when making a purchase, try to choose products from manufacturers that adopt advanced processing technologies and have a strict quality control system.

VI. Weigh the Price and After-sales Service Price is indeed one of the important factors to consider when purchasing leaf springs for semi-trailers, but you should never blindly pursue low prices and ignore product quality. Leaf springs with extremely low prices in the market are likely to have serious problems in terms of material selection, processing technology, etc. Using such products may seem to save costs in the short term, but during long-term use, there will be frequent failures and even safety hazards such as breakage. This will not only increase maintenance costs but also pose a huge threat to the safety of the vehicle and personnel, and ultimately, it will not be worth the loss. Conversely, products with too high prices may not necessarily fully meet your own actual needs. Therefore, when making a purchase, on the premise of ensuring that the product quality and performance meet the usage requirements of the semi-trailer, comprehensively compare the prices of leaf springs of different brands and specifications, and choose products with high cost performance.